311 minutes (65% of every work day)

spent on non-productive activities.

A time study conducted by consultant Joel Levitt confirmed yet again how small a percentage of an hourly maintenance worker’s time is spent on “direct actual work.” In a 480-minute work day, Levitt’s research found that a typical technician spends:

24 minutes

receiving instructions

57 minutes

getting tools/materials

72 minutes

traveling to/from tasks

38 minutes

coordination delays

24 minutes

idle at the job site

24 minutes

late starts/early quits

48 minutes

authorized breaks/relief

24 minutes

excess personal time

Understanding

Maintenance Triage

- Triage is a management protocol that structures the incoming workflow by priority so that the most critical work is attended to first.

- The practice is most often used in hospitals and other healthcare settings, becoming particularly important in response to disasters, battlefields or other emergencies.

- Triage also has applications in non-healthcare businesses by creating a structure for prioritizing projects, updates, publications, and other timely corporate needs.

Inefficient and unsafe maintenance

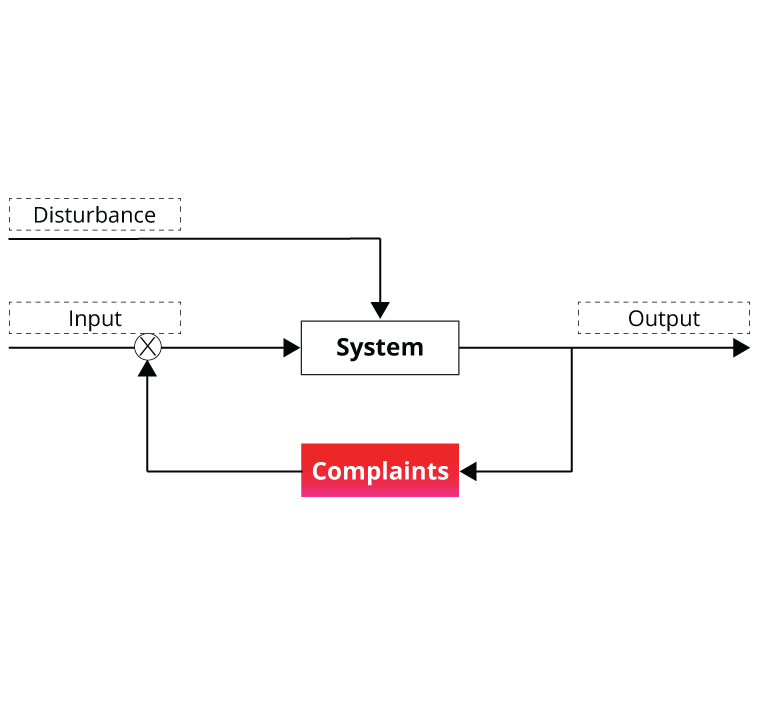

In maintenance, breakdowns are usually responded based on :-

First come, first serve.

Highest number of complaints.

Complainant's rank.

The Eisenhower

Decision Matrix

Maintenance triage safely responds based on the importance and urgency of equipment using Eisenhower Decision Matrix. The Eisenhower Matrix is a task management tool that helps you distinguish between urgent & important tasks so you can establish an efficient workflow.

Where importance is determined by : - equipment management number ≥ 12 and urgency is determined by history ≥ 0